We would like to give you a sneak peek into the process of building a Blauvent Art Canvas. Our partner is producing all in his facilities in Spain, fair and sustainable. Have a look on the steps from canvas weaving to the wood frame carpentry!

First of all the threads of cotton and polyester are woven to a raw canvas, thick and robust. The sound of the machines is loud, the room somewhat dusty, and very powerful. Centimetre by centimetre the raw cloth is growing and leaving the hectic weaving machine. Once this first step is accomplished it will be prepared in a big hall where hundreds of meters of this raw textile are waiting for their primer.

This canvas is different from most other canvas prints on the market, since all its components have fine arts material quality.

Closeup of the weft and warp, the matrix of our canvas.

The material mix used for the canvas is also depending for what the canvas will be used later on. As commercial printing places are using purely plastic based canvases, as they are cheap and easy to print on, high quality fabrics are composed of more cotton, linen, polyester fibres. In our case, as we are going for reproduction of art works, the fabric of choice is made out of a mix of 50% cotton and 50% polyester fibres. To prepare the surface for later printing or painting, a primer is applied to give the best results of color vibrance and durability.

Preparing a canvas with a glue and initial primer is essential.

The finished canvas products we offer are real fine art material, and despite it is a printed reproduction, one could paint over it with acrylic paint.

Drying row of canvas.

As the canvas is drying in the hall downstairs another essential part is produced in the carpentry just above. Wood coming from sustainable forestry of north Spain, dried by air is chosen and cut into peaces. These are then fed into a chain of automatic machines which allow to assemble a big number of different sized stretcher frames for all kind of purposes and dimensions. The main duty of such a strecher frame is of course to stretch the flexible canvas, and this without loosing tension for many years.

The craftsman’s of the canvas are Spains foremost art suppliers with long tradition and well established reputation. This is how their carpentry section is looking.

Their patented way of joining the edges of the stretcher frames is guaranteeing for durability and keeping the stretch of your Blauvent canvas.

Finished wooden frames.

On this image one of the masters wrapping a frame.

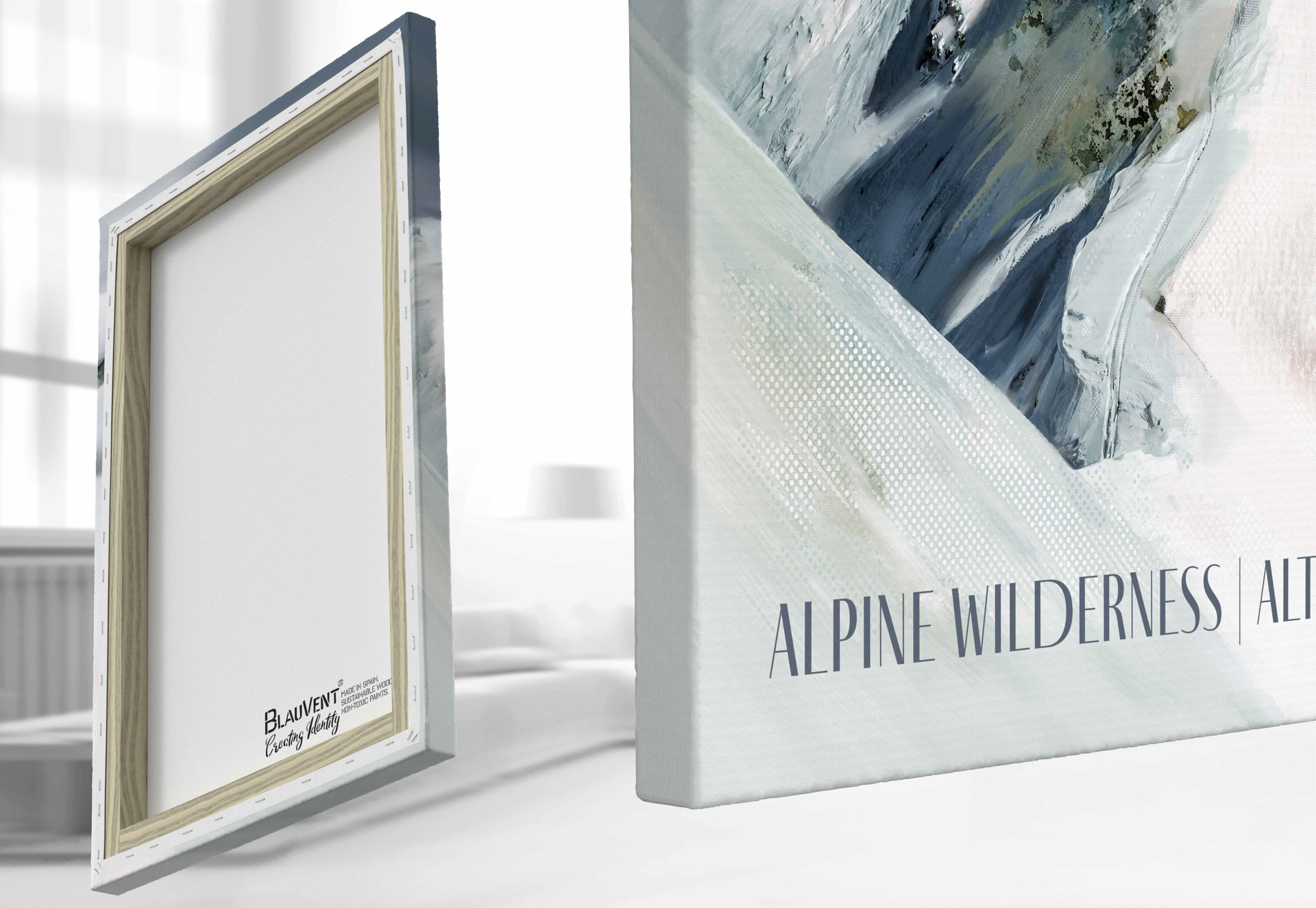

When we make an order the canvas is cut into the correct pieces, printed and later mounted on the stretcher frame. This is a another hand made process already very close to the finished product. You can see the original color of the canvas textile on the backside.

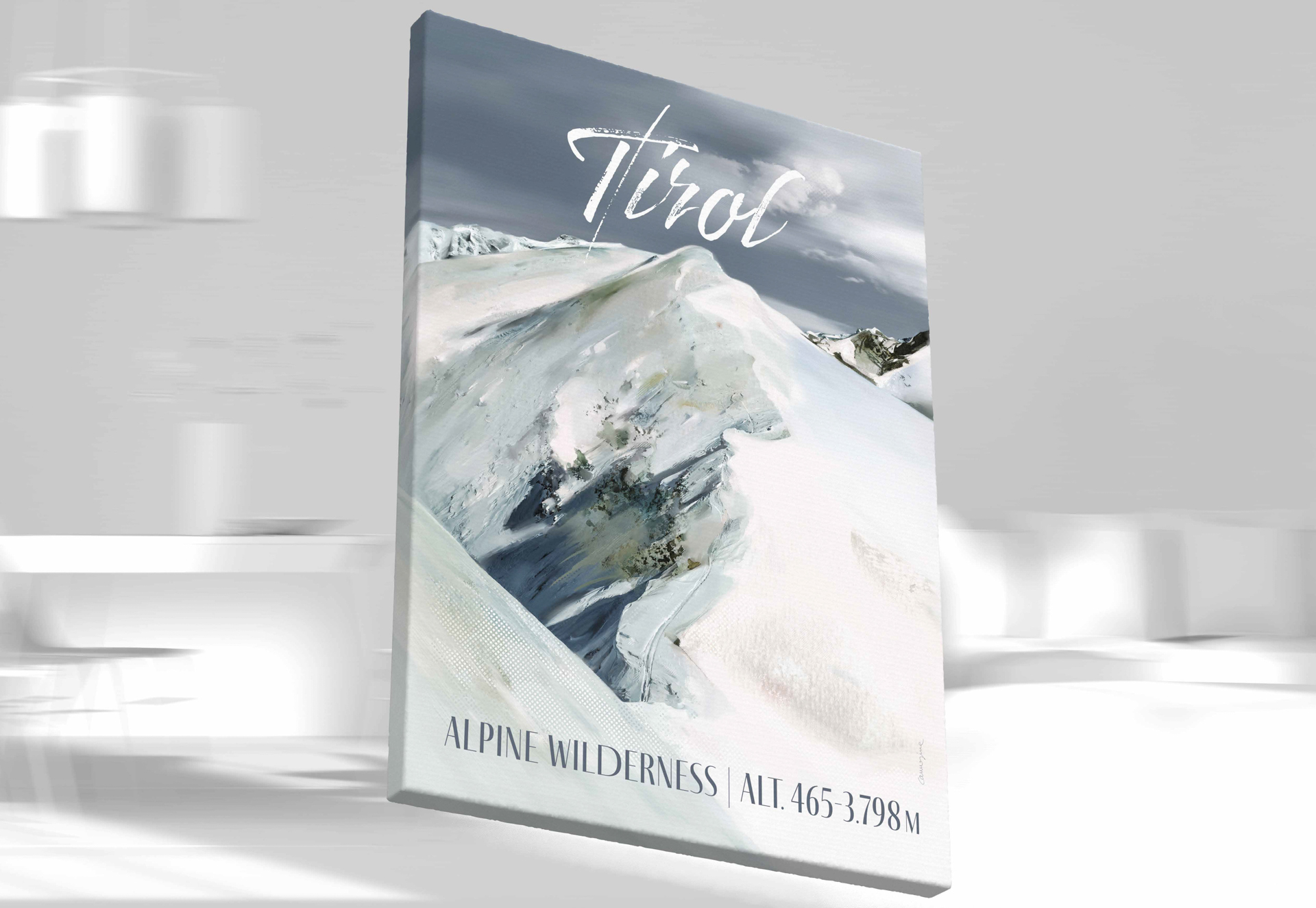

Blauvent creative potential is applied into a variety of wall art. From gallery standard canvas & paper productions to handcrafted wood plates. Quality Print of Blauvent Mountain Series Artworks on Canvas. Completely handmade in Spain.

The last step is applying the original Blauvent stamp, packing, securing the edges and eventually shipping.

We are happy and proud for our collaboration with this magnificent manufacturer and stay tuned for next blog posts where we will be explaining more on the process of how the artwork is created by Carmesine Studio.